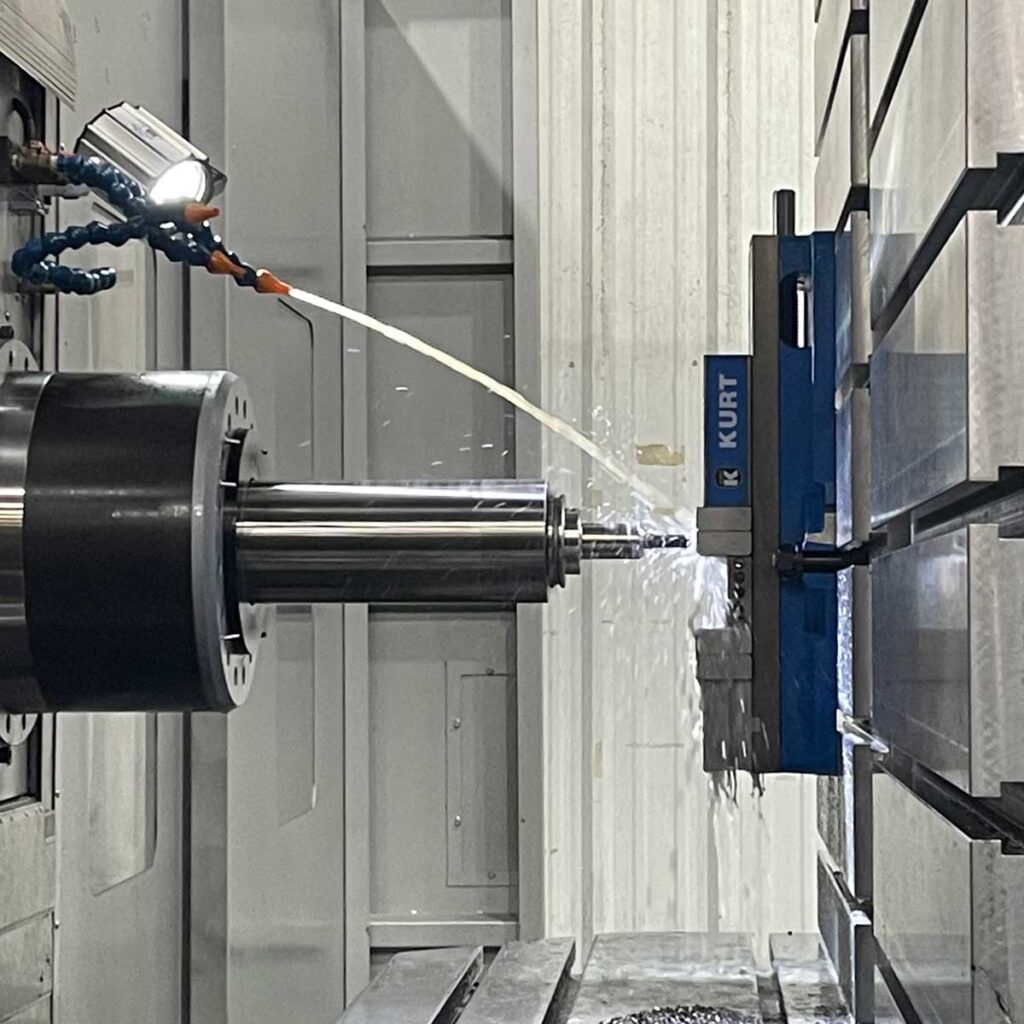

Abbott Tool is equipped with a wide range of advanced machinery capable of handling various needs.

Our machinery list includes an Ikegai NB110T CNC Horizontal Boring and Milling Machine, a Toyoda HB1620 CNC Horizontal Boring Mill, several mills such as the Haas UMC-750 5-Axis and VF-2, a Mazak Slant Turn 450 Lathe, a Hemel Microstar 325202M Coordinate Measuring Machine for inspection, a range of welding machines, grinders, saws, and even hydraulic presses.

With this vast array of machinery and tools, Abbott Tool is well-equipped to tackle a variety of projects.

Machine List

BORING MILL

1 Ikegai NB110T CNC Horizontal Boring and Milling Machine 57” x 78 3/4” x 68 5 Axis (X, Y, Z, W, B:4 AXES SIMULTANEOUSLY) W/Renshaw Probing System – Holds 14,000 pounds.

1 Toyoda HB1620 CNC Horizontal Boring Mill (X=118”, Y=82”, Z=59”, W=27”), Thru Spindle Coolant, 60 Pocket Tool Changer, B-Axis Rotary table, 0iMF Fanuc Controller, Renishaw Probe w/tool setter, Holds up to 44,000 lbs. (2022)

MILLS

COMPUTER SYSTEM

1 ECI/Job Boss2 Shop System-A Windows based, shop specific, software that automates and effectively controls all aspects of shop activity, from generating a quote, to creating a purchase order, tracking job time and shipping.

LATHES

INSPECTION EQUIPMENT

1 Starret Vertical Concentricity Gauge 14″ dia x 10′

WELDERS

1 Oxygen-Acetylene Cutting and Brazing

HONE

Saws

GRINDERS

PRESSES

KEYSEATER

MISCELLANEOUS